Sistine Chapel - Cultural heritage

Project description

The result is a unique and innovative system that maintains optimal climate conditions within the chapel, preserving the past for the benefit of generations to come.

Background

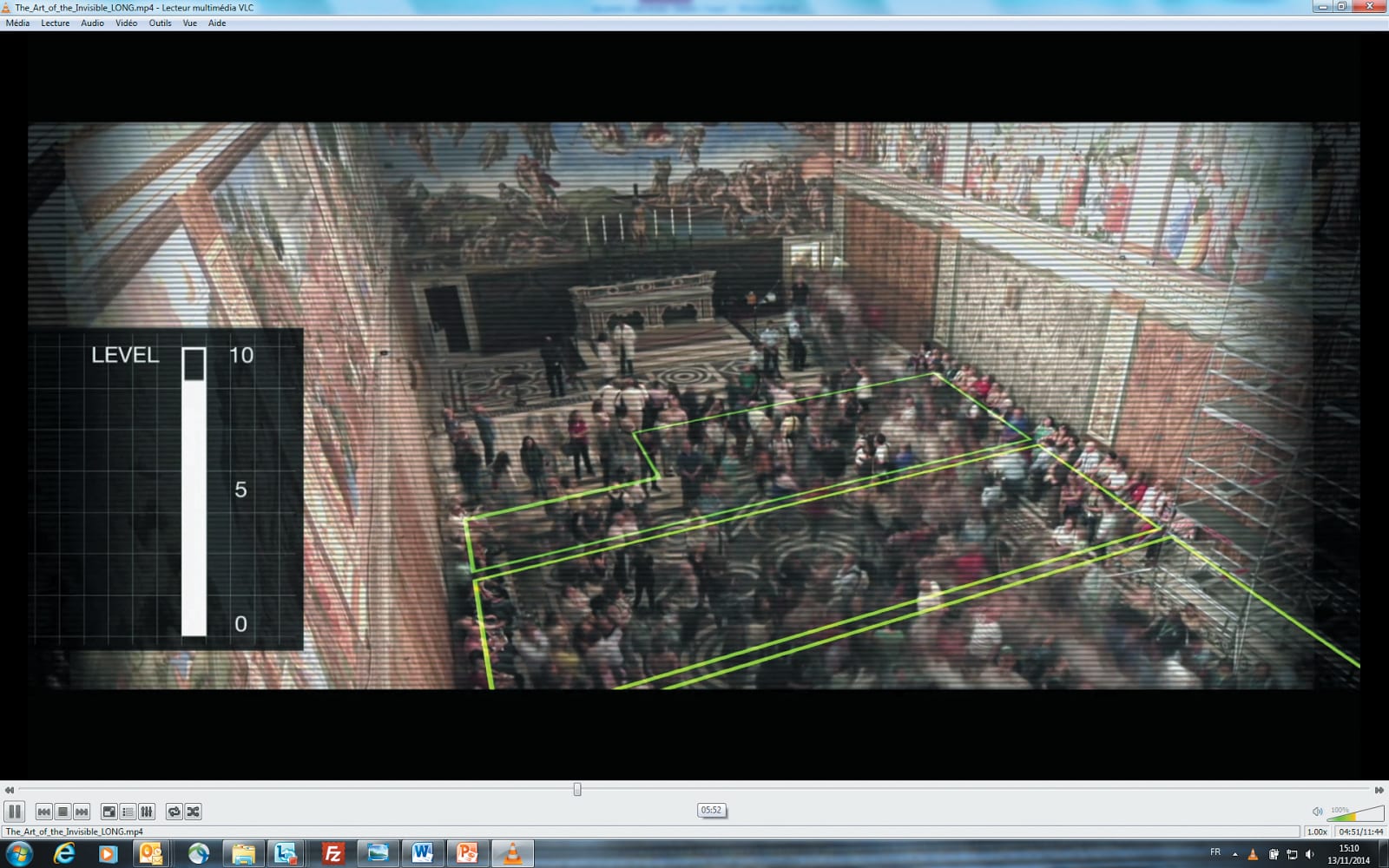

In 1993, Carrier designed and installed the Sistine Chapel's first air-conditioning system to accommodate a maximum load of 700 simultaneous visitors. During its lifetime, the system worked exactly as designed, but was not powerful enough to cope with the growing number of visitors.

The AdvanTEC team used advanced computer simulations to calculate airflow and analyse the climate within the chapel. Key focus areas included the critical parameters of consistent relative humidity, low air velocity, temperature stability and carbon dioxide concentration.

By harnessing the power of today's technology, international teams Carrier developed a unique HVAC solution to ensure the preservation of this World Heritage treasure capable of maintaining optimal conditions for up to 2,000 simultaneous visitors inside the Sistine Chapel.

- Respect the site's architecture

- Increase airflow capacity

- Control air velocity, quality, temperature and humidity

- Design high efficiency and energy-saving system

- Provide redundancy

- Maintain visitor access during installation

- Provide Service maintenance contract

- 30XWV580 Carrier AquaForce® chiller with Greenspeed® intelligence

- 39HQ Air Handling Unit

- FCL91 Dry Cooler: ventilated heat exchanger

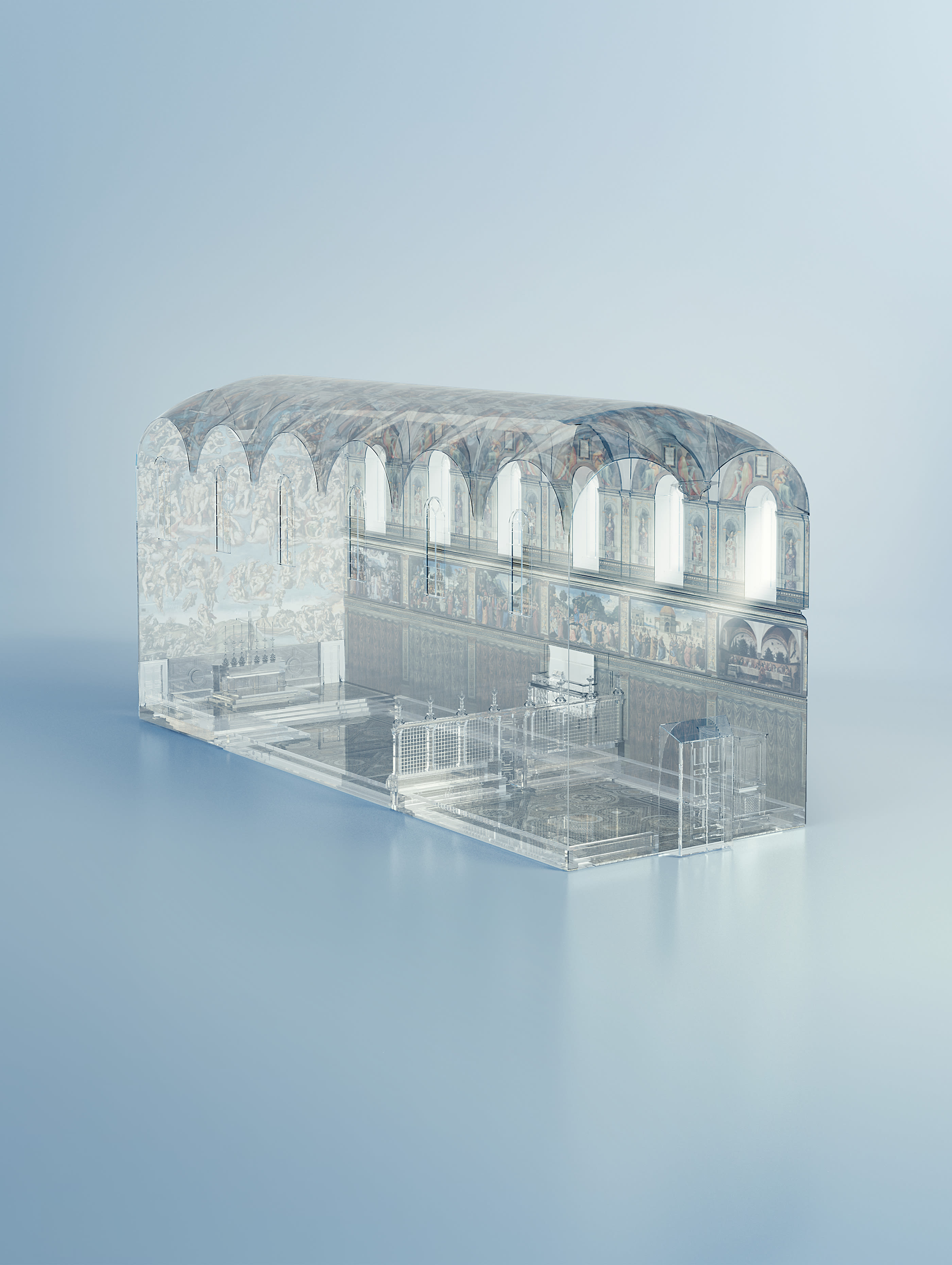

- Trumpet-shaped diffusers with diamond-shaped perforated plate: optimise the airflow and velocity to ensure "still air" conditions

- Building automation system which regulates and communicates real-time reports

The project presented a number of specific challenges and the resulting solution succeeded in:

- Efficiency - Twice as efficient than the previous system;

- Capacity - Three times greater capacity;

- "Invisibility" - The system, including sensors, cabling, air handling units, pumps, chillers and diffusers, are nearly invisible to the public;

- Air quality - Air handling units are equipped with six filtration levels;

- Noise control - The system is designed to deliver "church-quiet" levels operating at normal conditions;

- Innovation - A new energy-saving process application is being used for the first time;

- Functional redundancy provided by 2 identical subsystems/