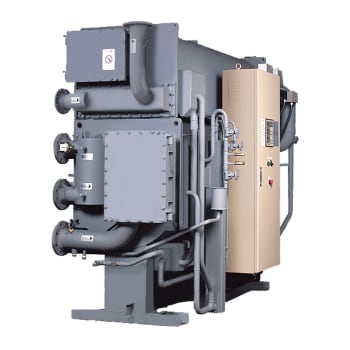

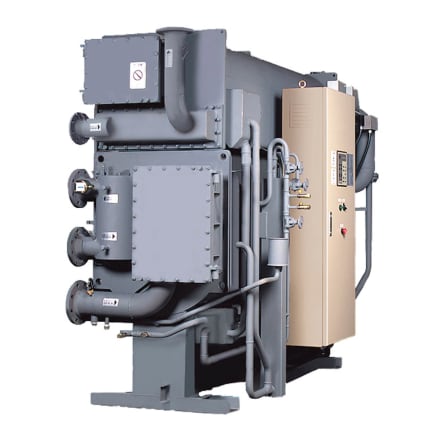

Single-effect hot water-fired absorption chiller

16LJ / 16LJ-F

Nominal cooling capacity : 80-4,000 kW

The Carrier 16LJ & 16LJ-F single-effect absorption chillers are designed to provide chilled water from waste heat sources generated from industrial processes and cogeneration systems.

- Complete range 80 to 4,000kW

- HFC-refrigerant free

- Hot water source from COPr up to 0.78

- Designed for cooling applications where low-pressure steam is available as waste heat

- Absorption chillers allow diversification of critical cooling requirements. Critical cooling loads are met with minimal electrical power input

- Allow smaller emergency generators compared to an electrical driven chiller

- Ozone-safe and CFC-free. Cooling requirements are met without chlorine-based refrigerants

- Absorption chillers reduce the contribution to global warming and minimise the global impact by greatly reducing electricity consumption and production of greenhouse gases

- The solution inhibitor has no impact on the environment

- An absorption chiller does not utilise mechanical moving parts, and this leads to quiet, vibration-free operation

- The use of high-efficiency heat transfer surfaces has reduced the space required for installation of the absorption chiller, resulting in a smaller footprint

- Expert self-diagnosis function to monitor operating conditions, predict chiller information and maintain stable operation

- Predictive maintenance information

- Carrier control system

- Fast digital PID control stabilises the chilled/ hot water temperature with high accuracy. It quickly responds to the load fluctuation and supplies stable chilled/hot water temperature. It is suitable for air-conditioning intelligent buildings which require sophisticated control

- High-performance purge system maintains the required operating pressure and minimises chiller maintenance to one purge operation per season (for year-round operation)

- Hot-water valve opening control

- Expansion of safe operating zone

- Crystallisation protection

- Designed for cooling applications where low-pressure steam is available as waste heat

- Absorption chillers allow diversification of critical cooling requirements. Critical cooling loads are met with minimal electrical power input

- Allow smaller emergency generators compared to an electrical driven chiller

- Ozone-safe and CFC-free. Cooling requirements are met without chlorine-based refrigerants

- Absorption chillers reduce the contribution to global warming and minimise the global impact by greatly reducing electricity consumption and production of greenhouse gases

- The solution inhibitor has no impact on the environment

- An absorption chiller does not utilise mechanical moving parts, and this leads to quiet, vibration-free operation

- The use of high-efficiency heat transfer surfaces has reduced the space required for installation of the absorption chiller, resulting in a smaller footprint

- Expert self-diagnosis function to monitor operating conditions, predict chiller information and maintain stable operation

- Predictive maintenance information

- Carrier control system

- Fast digital PID control stabilises the chilled/ hot water temperature with high accuracy. It quickly responds to the load fluctuation and supplies stable chilled/hot water temperature. It is suitable for air-conditioning intelligent buildings which require sophisticated control

- High-performance purge system maintains the required operating pressure and minimises chiller maintenance to one purge operation per season (for year-round operation)

- Hot-water valve opening control

- Expansion of safe operating zone

- Crystallisation protection