The flexibility of the 23XRV can assist with chilled water plant design requirements.

Carrier’s AquaEdge® 23XRV is the world’s first water-cooled variable speed screw chiller. The 23XRV combines the reliability of a screw compressor with the energy savings of a variable frequency drive (VFD).

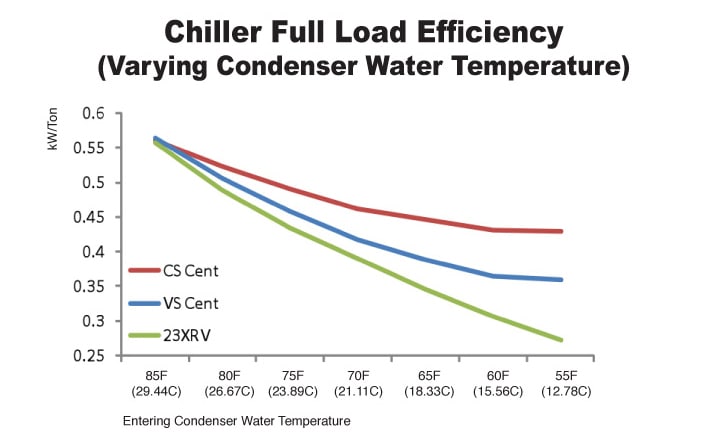

Chiller Efficiency

VFD chillers operate more efficiently than CS chillers at full load and lower entering condenser water.

The 23XRV can operate efficiently at ECdWT as low as 55°F (12.78°C) at most operating conditions.

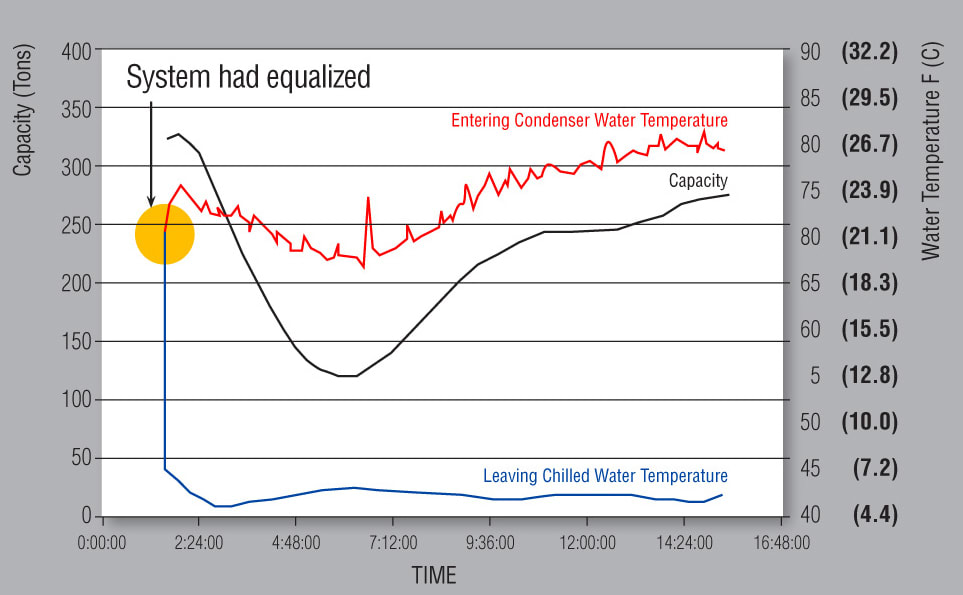

An inverted start is a chiller start-up where the condensing water loop temperature is lower than the chilled water loop. This condition is unusual for chiller operation, because it is typically differential pressure, from the high pressure condenser to the new low pressure evaporator that is the motivating force for refrigerant migration through the metering device. However, a unit start-up from an inverted position is occasionally required, such as during first start-up of the cooling season, or a Monday morning when the building is shut down over the weekend, or after coming out of water-side economizer operations, when low ambient temperatures drive down condensing loop water temperatures below those of the relatively warm, idle, chilled water loop. Integrated water-side economizers and large loop volumes serve to extend chilled loop pull down times. These circumstances must be accounted for in order to achieve a successful inverted start.

Because inverted starts are sometimes required, Carrier has designed the 23XRV to be capable of start-up in such a position. The standard start-up sequence of operation is depicted on the figure on the right.

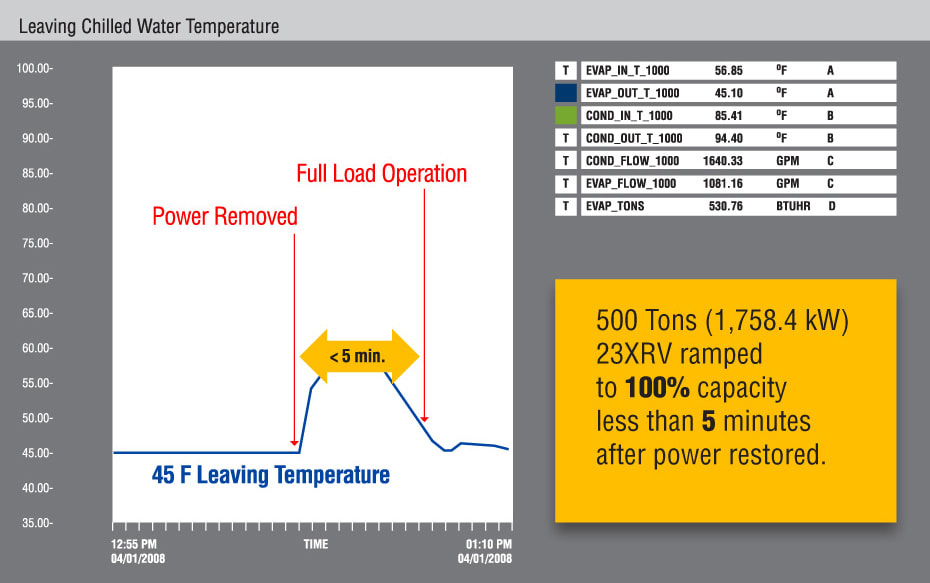

For mission critical applications such as data centers, the 23XRV variable speed screw chiller employs exclusive Capacity RECOVERY™ technology and control design, providing very fast full load cooling capacity recovery in a range of 4-6 minutes when building power resumes via a quick acting electric grid reconnection or generator system following an unexpected building or site power loss. The timing is based on industry AHRI design conditions and that water flows have resumed and no safety or system interlocks need a mechanical reset prior to recovery. Carrier's focus and the customer's benefit is a variable speed screw chiller that is designed to provide cooling capacity recovery quickly following an unexpected power interruption.

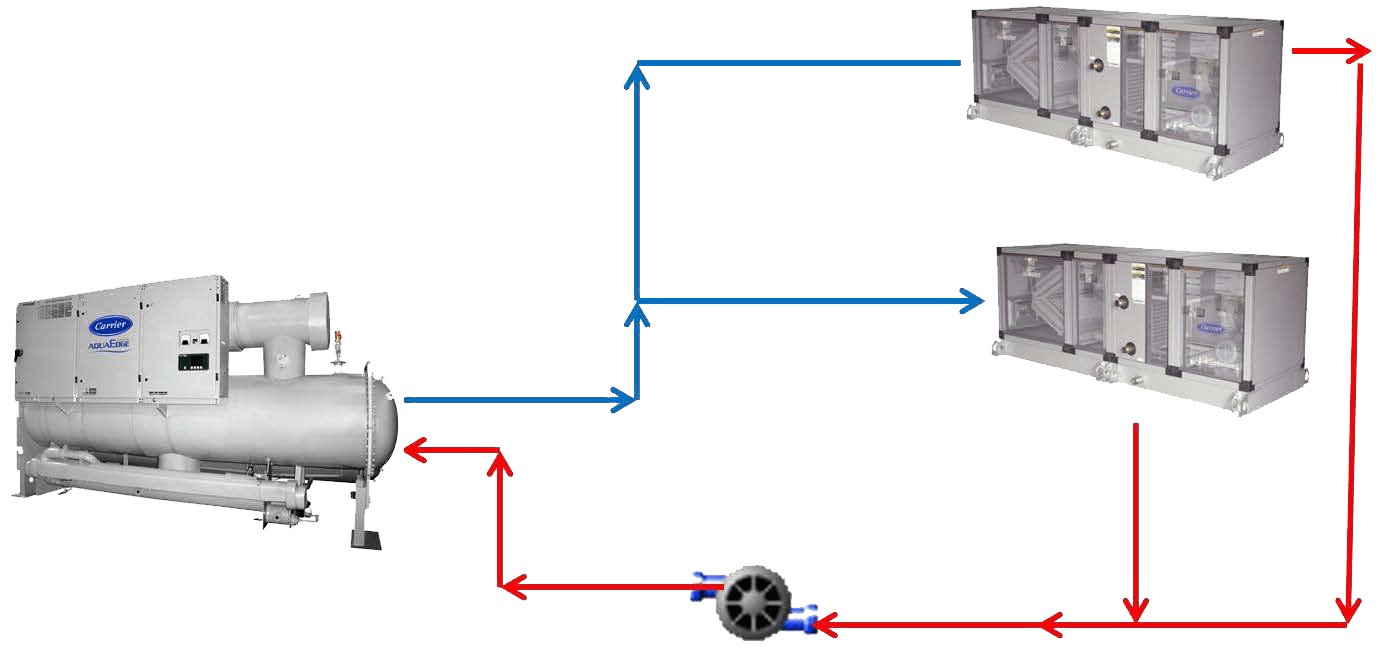

These three items all affect the magnitude of capacity transients on the chiller. Because they all affect the chiller’s performance in the same way, they will be discussed together here. All three relate to the time it takes the chilled water to cycle through the complete chilled water loop from the chiller to the load and back again. In order to understand how changing each parameter effects the chiller’s operation, a simple chilled water loop system diagram is useful.