Crate & Barrel

i-Vu® control system reduces energy costs and keeps Crate & Barrel customers comfortable, product-focused

Durham, NC

Crate & Barrel’s mission is People, Product, and Presentation. The Northbrook, IL-based company’s goal is to keep customers comfortable in the store so that they can maximize their exposure to the many houseware and furniture products that Crate & Barrel has to offer. Crate & Barrel stores typically use 12W/ft2 for lighting to create their target product environment, four times the average for a retail space. Consequently, the store’s thermal load from lighting is considerable — potentially impacting customers, employees and products — and store personnel must be able to control both lighting and heating, ventilation and air conditioning (HVAC) systems in a precise, flexible manner to preserve customer comfort and suitable humidity levels for optimum product quality. Prior to building a new facility in Durham, NC, Crate & Barrel consulted with the controls specialists at Carrier’s Melrose Park-based distributor, Temperature Equipment Corporation (TEC), to discuss an integrated solution.

Project Solution

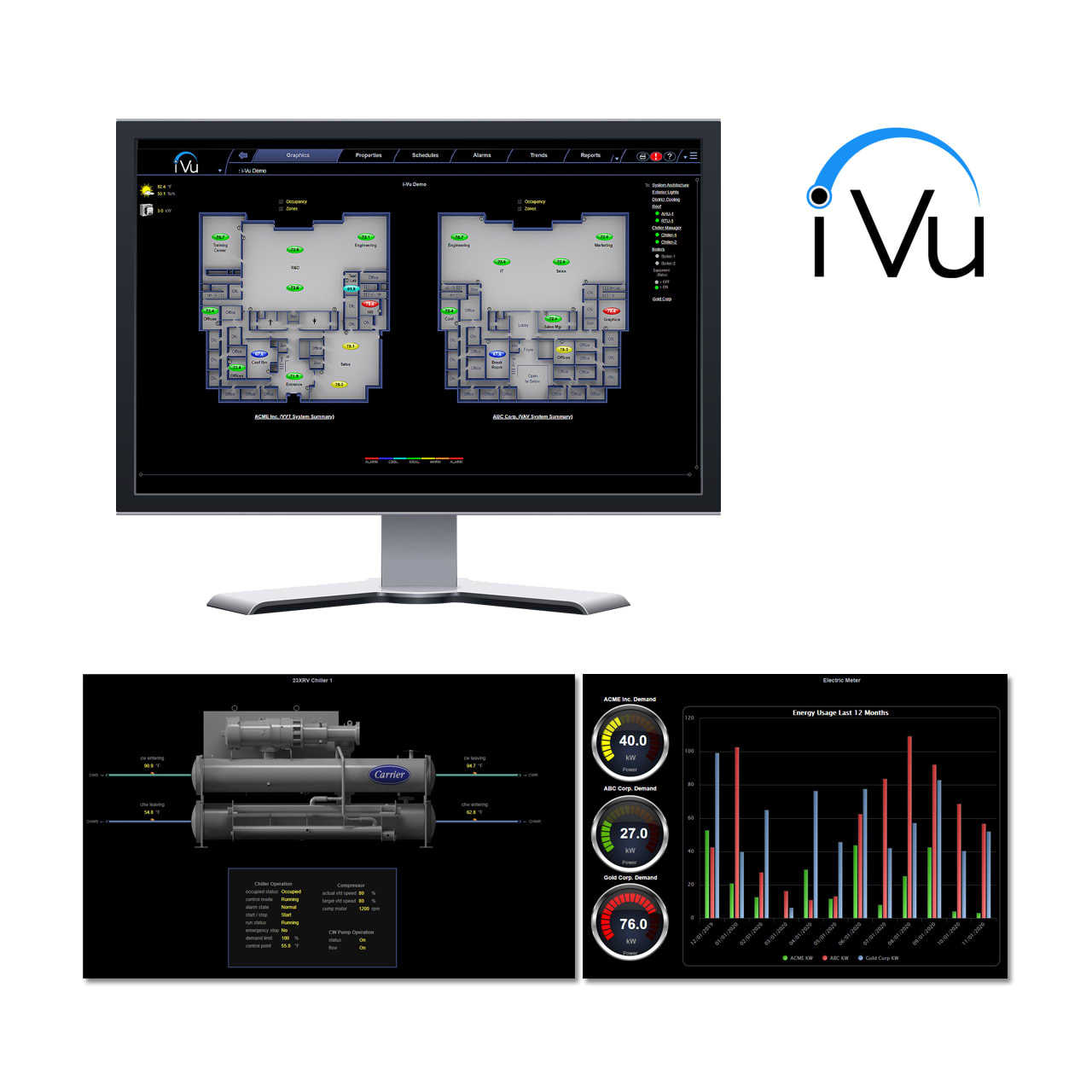

TEC designed a control system that integrated Crate & Barrel’s extensive lighting — more than a mile of track lighting incorporating some 1,000 fixtures — with its HVAC components, including 120 tons of cooling from rooftop units. BACnet® controls were installed on all the equipment in the store, from exhaust fans to lighting zones, plus sensors from BAPI®, Carrier and Veris for a total of 29 devices and 2,715 points. The i-Vu® Open control system by Carrier integrated all components and provided a user-friendly web interface which enabled fluid scheduling of both lighting and HVAC systems, providing store personnel with the capacity to maximize conditions for customers and products alike.

Controls