Maximize efficiency with series counterflow operation

In a series counterflow arrangement, the work done (lift) by each compressor is reduced, which significantly improves the efficiency of the chillers at full and part load conditions.

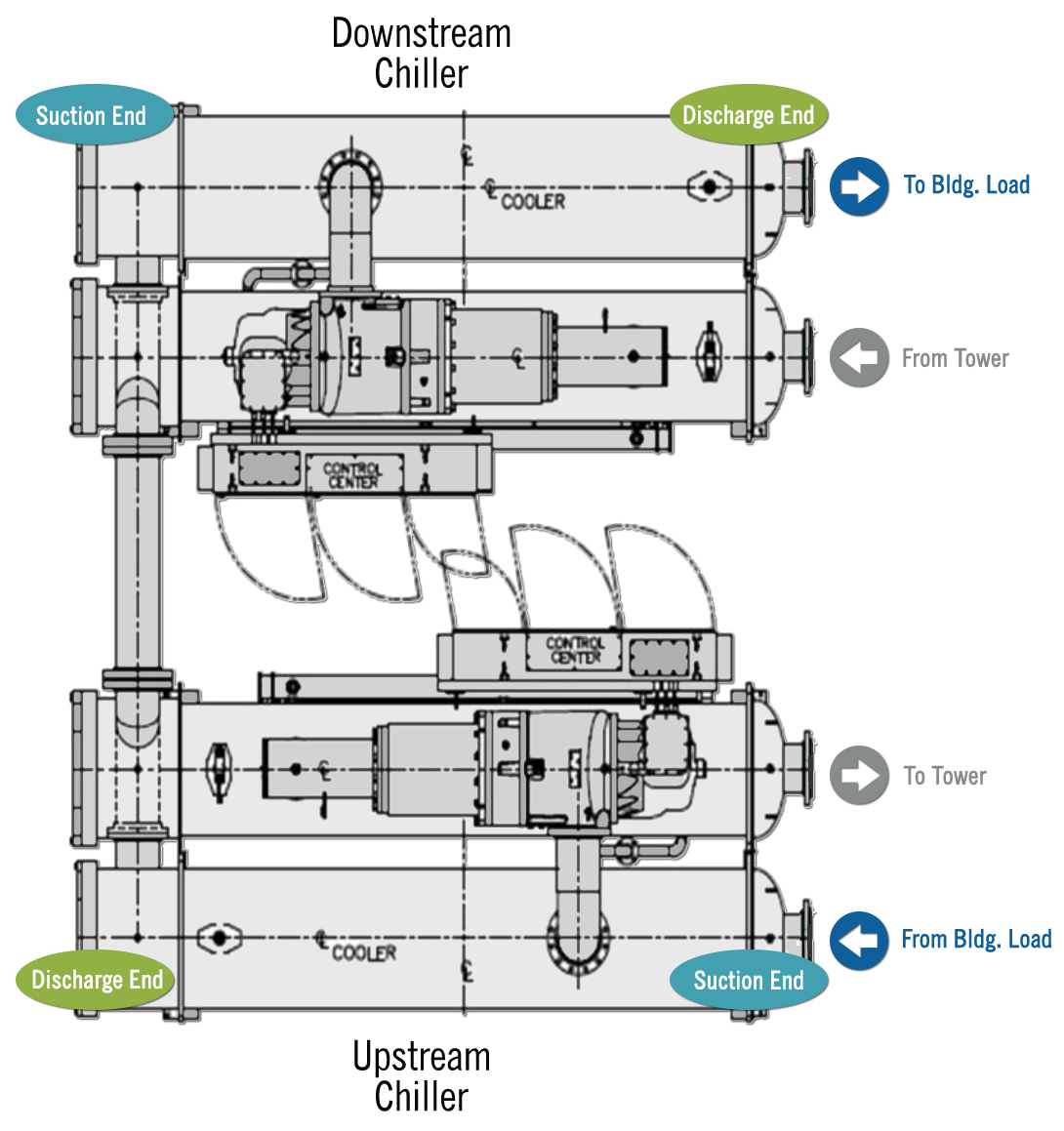

When two or more chillers are piped in series counterflow, then the following conditions are met:

- Water flows through an evaporator in series

- Water flows through the condenser in series

- Water flow in the evaporator is opposite of the water flow in the condenser, a counterflow arrangement (opposite to each other)

In a Series Counterflow arrangement, the work done (lift) by each compressor is reduced, which significantly improves the efficiency of the chillers at full and part load conditions.

The total lift produced by the Series Counterflow system can be up to 20% lower than a conventional parallel system. Lower lift means less work, and therefore a reduction in power consumption for a given cooling capacity.

This is what the experts are saying about Carrier's counterflow solution - "If you only need to run one chiller, you should only use one chillers worth of flow." "Compared to a parallel chiller arrangement , placing the chillers in series counterflow reduces the lift by approximately 6 degrees F, even on a design day. That is like finding a cooling tower with a 1 degree approach."

Maximize Efficiency with Series Counterflow (SCF)

- Up to 25 percent better full load efficiency than ASHRAE 90.1 2013 standards*

- Up to 47 percent better part load efficiency than ASHRAE 90.1 2013 standards*

- Up to 6 dbA quieter than parallel chillers

- Identical surge free screw chillers provide ease of operation and flexibility

- Constant or variable flow, N or N + 1 arrangements

- Carrier’s plant system manager with AdvanTE³C technology provides advanced control of chillers, pumps, towers, and more

"If you only need to run one chiller, you should only use one chiller's worth of flow"

- Reduced lift at design conditions. Don't rely on mother nature for lift reduction, provide your own with series counterflow.

- Identical chillers (not cascaded)

- 2:1 turndown for evaporator and pump savings, as well as variable primary flow chiller savings

- 2:1 turndown allows for side stream heat recovery unit

- Small footprint

- Series counterflow waterboxes are designed to accommodate piping

- High efficiency chiller for a high efficiency system

- Wide operating range (for both elevated temperatures and low lift operation)

- Patented control solution with ChillerVu plant manager controls

- Quick restart times

- Running redundancy capability

- Positive displacement prevents issues with surge

- Quick reaction time (70% per minute)

- Variable primary flow is an energy efficient solution to the chillers in series counterflow

- Sound reduction

- Capability to shut off pumps

- Either chiller can be the lead or lag