As sustainability requirements grow and operating costs increase, the need to move temperature-sensitive cargo around the globe at more efficient levels is more urgent than ever before. OptimaLINE makes this possible by delivering a step-change in efficiency and sustainability across multiple operating conditions. Building on the proven strengths of our bestselling PrimeLINE® platform, we combined the latest refrigeration technology from across our company and partners, so that OptimaLINE allows you to meet these new industry demands with confidence.

OptimaLINE™ Container Refrigeration Unit

Optimal Performance. Optimal Efficiency.

Introducing OptimaLINE™, our all-new container refrigeration platform engineered to deliver a step-change in efficiency, exactly where it matters to you.

Experience unmatched refrigeration efficiency levels across a wide range of operating conditions and load levels.

With evolving sustainability requirements and increased operating costs, you need a solution with even greater flexibility in order to adapt to new demands with confidence. And at Carrier Transicold, we’re constantly innovating to make it all possible.

With OptimaLINE, we’ve taken the proven strengths of PrimeLINE® and our optimized machine design with efficiency and reliability in mind, leveraging the latest innovations in reefer technology to set a new standard for the industry, while adding the critical versatility demanded of today’s fleets. From its variable speed compressor with its permanent magnet motor to its variable frequency drive, all of which are optimized for the task on hand, OptimaLINE combines multiple fundamental enhancements to decrease the energy consumption and operating costs of your fleet, enable tighter temperature controls and reduce your overall carbon footprint. And with Carrier Transicold, it’s all backed by the strength of our worldwide service network.

Enhance the efficiency and sustainability across your cold chain with a high-performing solution that doesn’t compromise when it comes to efficiency and reliability across different load levels. Explore our OptimaLINE container refrigeration platform today.

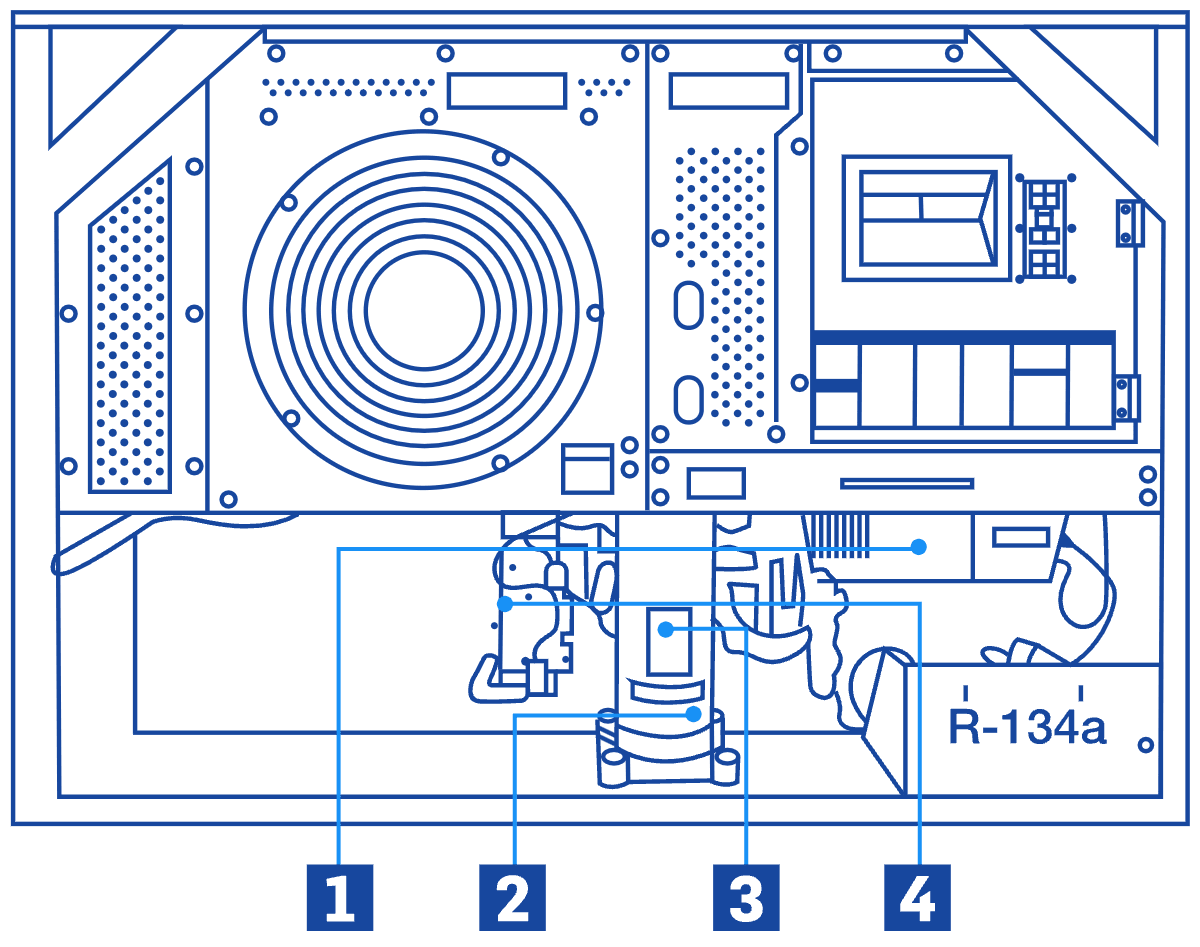

1. Variable frequency drive

Works with ML5 controller to ramp up or ramp down compressor speed to achieve and hold required temperature, for optimum efficiency at full or part load.

2. Variable speed compressor

Operates at the proper speed and torque to match the load required by the system conditions.

3. Permanent magnet motor

Provides greater efficiency compared with a standard induction motor.

4. Economizer circuit valve

The electronic expansion valve, along with the two-speed condenser fan, optimizes efficiency during all operating conditions.

Adding OptimaLINE to your fleet brings you a whole host of powerful benefits:

Step-Change in Efficiency15% less power draw compared with previous units |

Greater Environmental Sustainability*Up to 40% greater reduction of carbon dioxide (CO2) emissions

|

OptimaLINE™ Container Refrigeration Unit

- Introducing OptimaLINE, our latest and most innovative container refrigeration system that delivers step-change in efficiency and performance.

- Experience unmatched refrigeration efficiency levels across a wide range of operating conditions and load levels.

- Low energy consumption and reduced annual energy costs by up to 26% at pure partload, as compared to previous Carrier units.

- 10% more efficient from previous Carrier units, at 85% part-load, yielding significant operational cost savings and ultimately, reducing overall carbon footprint.

Step-change in efficiency

- Exclusive HFC-134a variable speed scroll compressor (R-513a and R-1234yf ready) with permanent magnet motor

- Zero ODP HFC-134a

- High-efficiency evaporator and extruded Micro-channel condenser coils

- Electrostatically coated all-aluminium condenser coil

- High-efficiency vane-axial aero technology evaporator fans

- Three-phase dual speed condenser and dual-speed evaporator fan motors

- Electronic expansion valves for Evaporator and Economizer circuits

- Refrigerant receiver with two stainless steel sight glasses, one with integral moisture eye

- ATO (Sprenger)-accepted adjustable fresh-air exchange (with micro and macro settings)

- CE marking

Cooling Capacity: Ambient @ 38°C (100°F) with Exclusive HFC-134a Scroll Compressor @ 460v 60Hz

| Temperature | Watts | Btu/hr |

|---|---|---|

| 2°C (35°F) | 12,500 | 42,600 |

| -18°C (0°F) | 6,800 | 23,200 |

Specifications are subject to change without notice.

Carrier reserves the right to discontinue or change any specification or design without prior notice or obligation.

Step-change in efficiency

- Exclusive HFC-134a variable speed scroll compressor (R-513a and R-1234yf ready) with permanent magnet motor

- Zero ODP HFC-134a

- High-efficiency evaporator and extruded Micro-channel condenser coils

- Electrostatically coated all-aluminium condenser coil

- High-efficiency vane-axial aero technology evaporator fans

- Three-phase dual speed condenser and dual-speed evaporator fan motors

- Electronic expansion valves for Evaporator and Economizer circuits

- Refrigerant receiver with two stainless steel sight glasses, one with integral moisture eye

- ATO (Sprenger)-accepted adjustable fresh-air exchange (with micro and macro settings)

- CE marking

Cooling Capacity: Ambient @ 38°C (100°F) with Exclusive HFC-134a Scroll Compressor @ 460v 60Hz

| Temperature | Watts | Btu/hr |

|---|---|---|

| 2°C (35°F) | 12,500 | 42,600 |

| -18°C (0°F) | 6,800 | 23,200 |

Specifications are subject to change without notice.

Carrier reserves the right to discontinue or change any specification or design without prior notice or obligation.