PowerLINE UG15 Tier 4 Interim

69UG15-068S-05

Power you'll get simply attached to.

- Industry-leading PowerLINE® generator sets from Carrier Transicold are designed and built for one purpose: continuous, unattended operation for all refrigerated containers transported by road or rail. PowerLINE generator sets offer the ideal combination of horsepower, torque, and motor-starting capability and provide power to start any ISO reefer, anywhere it’s necessary.

- Whether you choose clip (RG15) or undermount (UG15), PowerLINE generator sets provide more mounting flexibility. Attaching and disconnecting the generator set can take just minutes.

- For clip-on mounting, the RG15 pin-mounting bracket design saves time; for clamp mounting, the self-aligning ratcheted clamp locks allow safe, secure attachment to corner castings.

- For undermount, you can choose standard four-point mounting or our exclusive QuickMount™ design available on the UG15 generator set.

- Outstanding convenience and safety make the PowerLINE generator set number one for operating control. Up-front analog instrumentation is easy to read and allows immediate access to key operating parameters. The control system is uncomplicated, easy to access and troubleshoot.

- The Tier 4 interim PowerLINE generator set is built with an export engine, belongs in the 19-37 KW class and meets emission levels specified by the US EPA Tier 4 interim emission standard. The units built with these export engines are exclusively for sale/use outside the United States.*

*See Exhibit B for additional information.

RUGGED CONSTRUCTION, DEPENDABLE POWER, SIMPLE OPERATION.

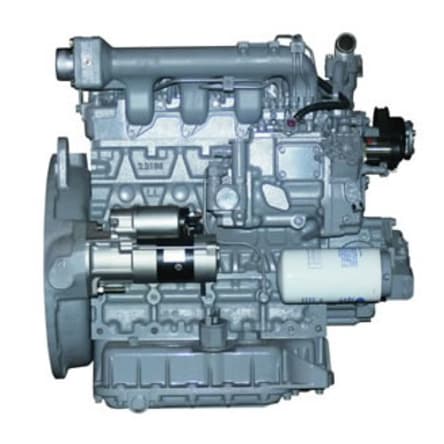

The PowerLINE® unit contains a 23.9 KW V2203-DI* engine and a 15 kW field wound generator. The engine includes an electronic governor system that provides near-constant engine speed, which results in more stable voltage output. The powerful, reliable; low- maintenance field wound generator produces 460 volts of continuous power and features an internally excited, self-regulated design. All electrical components are enclosed within the generator package and provide superior resistance to moisture and salt.

The model 69UG15 is designed to mount to a variety of ISO container chassis with I beam centers of 36-38 inch (91-96 cm) center- line separation and 10 inch (24.4 cm) minimum height.

The available FuelWise™ option can reduce fuel consumption up to 28%. This directly translates to a reduction of the unit’s carbon footprint by up to 28%.

*The engine meets the emission standard of the US EPA Tier4i, and this unit is offered only for export. See Exhibit B for additional information.

APPRECIATE THESE ADDITIONAL SYSTEM ADVANCEMENTS.

- Simple, easy-to-operate, reliable.

- V2203-DI 4-cylinder, water-cooled, 2.2-liter direct-injection32 HP/23.9 KW diesel engine which meets EPA Tier 4 interim standard (unit only for export outside the US).*

- Nominal 15 kW brushless, self-regulated generator, 460V output.

- All-steel fabricated frame with standard 4 point mounting or quick clamps system for easy attachment/ detachment from chassis.

- Frame and sheet metal components powder-coated for durability and superior corrosion protection.

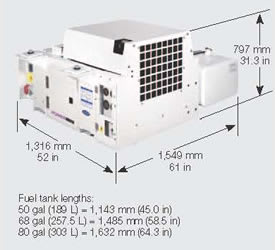

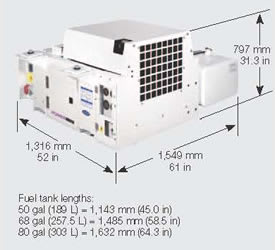

- 50, 68, 80 gallon fuel tank options.

- Carrier full-flow spin-on oil filter with internal bypass filtration is standard in all units and extends service intervals.

- Integral fuel filter with water separator and fuel heater.

- Fuel heater/warmer.

- External In-line fuel strainer with clear bowl strains larger particles in fuel prior to entering the lift pump. The clear bowl allows visual inspection of the screen for clogging.

- High-efficiency air cleaner (standard dry element, optional oil bath). Dry element, “cartridge”-style air filter with filter-minder allows for quick visual check of filter condition and signals when cartridge must be replaced.

- Self-tensioning, flexible, Poly V belt eliminates the need for an idler pulley and the guesswork associated with manual tensioning. Optimum tension provided by the belt helps assure maximum life of the water pump bearing.

- Stainless steel exhaust .

- Patented E-coat tube and fin radiator.

- 12V DC maintenance-free battery and solid state battery charger.

- Large oil pan capacity extends running hours between oil changes.

- Large aluminum service access door with quick-release latch , Battery access door, Stainless steel hinges and hardware, Driver-side controls.

- Forklift pockets allow mounting from either side.

- Safety stop controls for low oil pressure, high water temperature.

- FuelWise™ Option provides savings up to 28% versus single speed units.

*See Exhibit B for additional information

Ambient temperature range:

1. Structure -40 to +52°C (-40 to +125°F)

2. Operation - Start -26 to +52°C (-15 to +125°F)

2. Operation - Run -40 to +52°C (-40 to +125°F)

Functionality - The UG provides a full 15kW output to power ISO reefer containers.

Approximate Weights:

705 kg (1,555 lb.) with 50-gallon integral steel tank, less fuel

674 kg (1,485 lb.) with 50-gallon integral aluminum tank, less fuel

717 kg (1,580 lb.) with 68-gallon integral fuel tank, less fuel

710 kg (1,545 lb.) with 80-gallon integral aluminum tank, less fuel

RUGGED CONSTRUCTION, DEPENDABLE POWER, SIMPLE OPERATION.

The PowerLINE® unit contains a 23.9 KW V2203-DI* engine and a 15 kW field wound generator. The engine includes an electronic governor system that provides near-constant engine speed, which results in more stable voltage output. The powerful, reliable; low- maintenance field wound generator produces 460 volts of continuous power and features an internally excited, self-regulated design. All electrical components are enclosed within the generator package and provide superior resistance to moisture and salt.

The model 69UG15 is designed to mount to a variety of ISO container chassis with I beam centers of 36-38 inch (91-96 cm) center- line separation and 10 inch (24.4 cm) minimum height.

The available FuelWise™ option can reduce fuel consumption up to 28%. This directly translates to a reduction of the unit’s carbon footprint by up to 28%.

*The engine meets the emission standard of the US EPA Tier4i, and this unit is offered only for export. See Exhibit B for additional information.

APPRECIATE THESE ADDITIONAL SYSTEM ADVANCEMENTS.

- Simple, easy-to-operate, reliable.

- V2203-DI 4-cylinder, water-cooled, 2.2-liter direct-injection32 HP/23.9 KW diesel engine which meets EPA Tier 4 interim standard (unit only for export outside the US).*

- Nominal 15 kW brushless, self-regulated generator, 460V output.

- All-steel fabricated frame with standard 4 point mounting or quick clamps system for easy attachment/ detachment from chassis.

- Frame and sheet metal components powder-coated for durability and superior corrosion protection.

- 50, 68, 80 gallon fuel tank options.

- Carrier full-flow spin-on oil filter with internal bypass filtration is standard in all units and extends service intervals.

- Integral fuel filter with water separator and fuel heater.

- Fuel heater/warmer.

- External In-line fuel strainer with clear bowl strains larger particles in fuel prior to entering the lift pump. The clear bowl allows visual inspection of the screen for clogging.

- High-efficiency air cleaner (standard dry element, optional oil bath). Dry element, “cartridge”-style air filter with filter-minder allows for quick visual check of filter condition and signals when cartridge must be replaced.

- Self-tensioning, flexible, Poly V belt eliminates the need for an idler pulley and the guesswork associated with manual tensioning. Optimum tension provided by the belt helps assure maximum life of the water pump bearing.

- Stainless steel exhaust .

- Patented E-coat tube and fin radiator.

- 12V DC maintenance-free battery and solid state battery charger.

- Large oil pan capacity extends running hours between oil changes.

- Large aluminum service access door with quick-release latch , Battery access door, Stainless steel hinges and hardware, Driver-side controls.

- Forklift pockets allow mounting from either side.

- Safety stop controls for low oil pressure, high water temperature.

- FuelWise™ Option provides savings up to 28% versus single speed units.

*See Exhibit B for additional information

Ambient temperature range:

1. Structure -40 to +52°C (-40 to +125°F)

2. Operation - Start -26 to +52°C (-15 to +125°F)

2. Operation - Run -40 to +52°C (-40 to +125°F)

Functionality - The UG provides a full 15kW output to power ISO reefer containers.

Approximate Weights:

705 kg (1,555 lb.) with 50-gallon integral steel tank, less fuel

674 kg (1,485 lb.) with 50-gallon integral aluminum tank, less fuel

717 kg (1,580 lb.) with 68-gallon integral fuel tank, less fuel

710 kg (1,545 lb.) with 80-gallon integral aluminum tank, less fuel