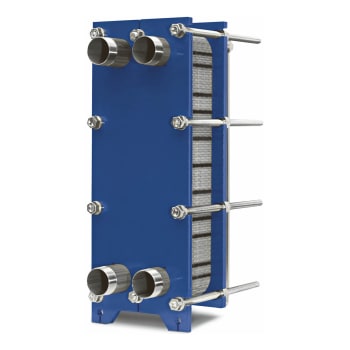

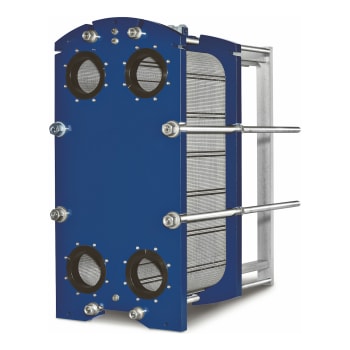

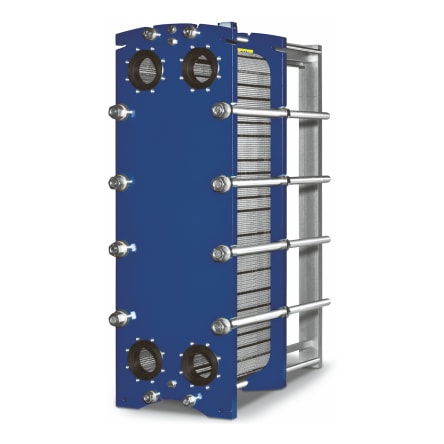

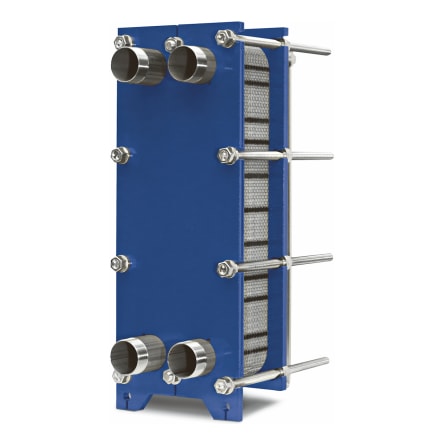

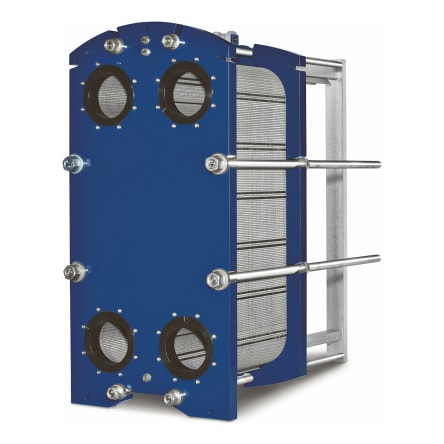

Gasketed plate heat exchanger

10TE

Gasketed plate heat exchangers are particularly well-suited for a wide range of applications: Heating of water (domestic, swimming pool...), Buffer on heat pump, Geothermal energy, Industrial processes...

- Decoupling of the machines to the system

- Cost efficient design

- Qualified and reliable

- High heat transfer coefficient

- Close temperature approach

- Large range capable to handle water flow rate up to 800m3/h

- Connection sizes available: DN 32, DN 50, DN 65, DN 80, DN 100, DN 150, DN 200

Gasketed plate heat exchanger consists of a number of corrugated heat transfer plates compressed by means of tightening bolts between a front fixed frame plate and a rear movable frame plate.

- Excellent heat transfer coefficient

- Very low pinch point temperatures possible

- High corrosion resistance

- Compact footprint

- Easy to install and to maintain

- Low-capacity circuits and fluid retention volume

- Possibility of heat transfer area extension

- Maximum differential pressure equal to maximum operating pressure

TF insulation (DN 32, DN 50 and DN 65 models)

Thermoformed and semi-rigid prefabricated case easy to install and to adjust to the specific configuration of the heat exchanger and to eventual particular customer needs.

- Special “double-layered” structure

- Can be easily and quickly assembled

- Minimized energy losses and condensation

- Higher level of safety and comfort

- Easy to adapt on site to all products configurations and to adjust to customers needs

- Low installation costs

- Lightweight and resilient

PB insulation (DN 80, DN 100, DN 150 and DN 200 models)

Self-supporting modular structure made with insulating panels. Two aluminum foils coupled to the polyurethane foam ensure high thermal insulation, good structural rigidity and appropriate surface finish.

- Easily and quickly assembled

- Minimized energy losses and condensation

- Higher level of safety and comfort

- Low installation costs

- Quick and easy access to the heat exchanger for inspection

Dip tray (all models)

Safeguard device specifically designed to collect water or other fluids in case of unexpected fluid leakage or when the heat exchanger is open for maintenance.

- Reduced risk of flooding in case of condensate, unexpected fluid leakage

- Possibility to adjust tilt to facilitate drainage

- Low installation costs

Double Wall Plates

Double-wall plates consist of two identical heat transfer plates embossed together and then joined by laser welding around the inlet and outlet portholes.

- Generate a thin air gap between the two plates that prevents fluids intermixing and brings to an external leakage visually detectable

- Provide the right solution for all those HVAC applications where a higher level of safety is recommendable and/or required

Plate Pack Protection

The Plate Pack Protection is a safeguard device specifically designed to protect personnel in case of unexpected leakage. It should be always used when temperatures are over 60°C also when handling uncritical media.

- Consists of two or more metal sheets sharped to cover the plate pack and to fit the plate heat exchangers

- Supplied as a kit

- Protection of the plate pack in case of aggressive or polluted environment

- Large range capable to handle water flow rate up to 800m3/h

- Connection sizes available: DN 32, DN 50, DN 65, DN 80, DN 100, DN 150, DN 200

Gasketed plate heat exchanger consists of a number of corrugated heat transfer plates compressed by means of tightening bolts between a front fixed frame plate and a rear movable frame plate.

- Excellent heat transfer coefficient

- Very low pinch point temperatures possible

- High corrosion resistance

- Compact footprint

- Easy to install and to maintain

- Low-capacity circuits and fluid retention volume

- Possibility of heat transfer area extension

- Maximum differential pressure equal to maximum operating pressure

TF insulation (DN 32, DN 50 and DN 65 models)

Thermoformed and semi-rigid prefabricated case easy to install and to adjust to the specific configuration of the heat exchanger and to eventual particular customer needs.

- Special “double-layered” structure

- Can be easily and quickly assembled

- Minimized energy losses and condensation

- Higher level of safety and comfort

- Easy to adapt on site to all products configurations and to adjust to customers needs

- Low installation costs

- Lightweight and resilient

PB insulation (DN 80, DN 100, DN 150 and DN 200 models)

Self-supporting modular structure made with insulating panels. Two aluminum foils coupled to the polyurethane foam ensure high thermal insulation, good structural rigidity and appropriate surface finish.

- Easily and quickly assembled

- Minimized energy losses and condensation

- Higher level of safety and comfort

- Low installation costs

- Quick and easy access to the heat exchanger for inspection

Dip tray (all models)

Safeguard device specifically designed to collect water or other fluids in case of unexpected fluid leakage or when the heat exchanger is open for maintenance.

- Reduced risk of flooding in case of condensate, unexpected fluid leakage

- Possibility to adjust tilt to facilitate drainage

- Low installation costs

Double Wall Plates

Double-wall plates consist of two identical heat transfer plates embossed together and then joined by laser welding around the inlet and outlet portholes.

- Generate a thin air gap between the two plates that prevents fluids intermixing and brings to an external leakage visually detectable

- Provide the right solution for all those HVAC applications where a higher level of safety is recommendable and/or required

Plate Pack Protection

The Plate Pack Protection is a safeguard device specifically designed to protect personnel in case of unexpected leakage. It should be always used when temperatures are over 60°C also when handling uncritical media.

- Consists of two or more metal sheets sharped to cover the plate pack and to fit the plate heat exchangers

- Supplied as a kit

- Protection of the plate pack in case of aggressive or polluted environment