About The Author: Travis Baugh is a Digital Brand Marketing Manager for Carrier, where he develops informative, straightforward content to help homeowners better understand heating, cooling, and indoor air quality. His writing is focused on empowering homeowners to make confident, well-informed choices about their home comfort systems.

HVAC Education, Furnaces

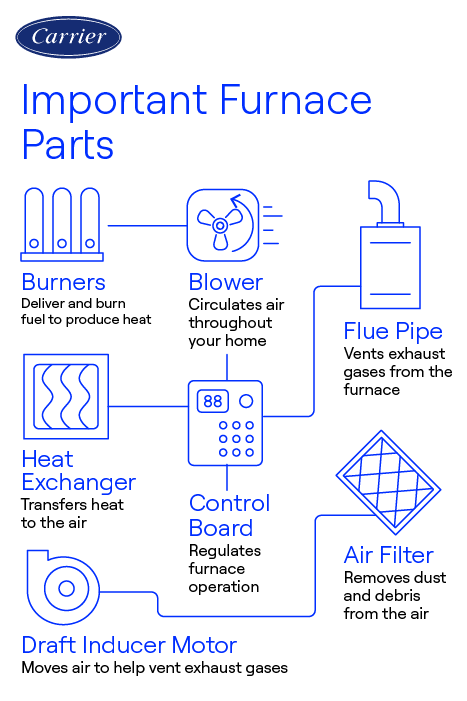

Understanding the Different Furnace Parts and Their Functions

A furnace is a complex system with many components that work together to provide warmth and comfort in your home. Understanding the various parts of your furnace and their functions can help you maintain the system effectively, identify potential issues, and ensure it operates efficiently. Here’s a breakdown of the most essential furnace components and their roles.

10 Furnace Parts And Their Roles In Keeping You Comfortable

1. Burner

The burner is responsible for igniting the fuel, whether it’s natural gas, propane, or oil, to create heat. When the furnace thermostat detects that the temperature in your home has dropped, it signals the burner to activate. The burner releases gas into a combustion chamber where it’s ignited by the ignition system, and the combustion process begins.

2. Heat Exchanger

The heat exchanger is one of the most vital components of your furnace. Once the burner ignites the fuel, the heat exchanger absorbs the heat generated by the combustion process. It then transfers this heat to the air that flows through the furnace. The heat exchanger is designed to ensure the hot gases from the combustion process don’t mix with the air that is circulated through your home. This component is crucial for maintaining air quality while efficiently heating your home.

3. Blower Motor

The blower motor is responsible for circulating the heated air from the furnace throughout your home. Once the heat exchanger warms the air, the blower motor pushes it through the ductwork to the vents in different rooms. The blower is also responsible for pulling cooler air into the furnace to be heated. The motor works in tandem with the thermostat to maintain the desired temperature by adjusting the fan speed based on demand.

4. Thermostat

The thermostat is the control center for your furnace. It monitors the temperature in your home and signals the furnace to activate when it senses that the room temperature has dropped below the set level. Once the furnace reaches the desired temperature, the thermostat sends a signal to shut it off. Modern thermostats allow for precise temperature control, and many are programmable to save energy and optimize comfort.

5. Flame Sensor

The flame sensor is a safety device that ensures the burner is operating correctly. It detects the presence of a flame in the combustion chamber. If the flame sensor does not detect a flame, it will shut down the gas supply to prevent unburned gas from accumulating, which could cause a dangerous situation. A faulty flame sensor is one of the common reasons a furnace might fail to ignite.

6. Gas Valve

The gas valve controls the flow of gas to the burner. When the thermostat signals the furnace to turn on, the gas valve opens to allow gas to flow to the burner. If the valve is malfunctioning, it can prevent the furnace from igniting, or it could result in a dangerous gas leak. Properly functioning gas valves are crucial for safe and efficient furnace operation.

7. Inducer Fan

The inducer fan is responsible for ensuring proper airflow through the furnace, particularly for venting combustion gases out of the furnace. It creates negative pressure inside the combustion chamber to draw gases away from the burner and direct them out through the exhaust system. The inducer fan is crucial for preventing the buildup of dangerous carbon monoxide in the home.

8. Control Board

The control board is essentially the brain of the furnace. It manages all the electrical components and ensures they work in harmony. It controls the burner, blower motor, inducer fan, and other components based on the signals it receives from the thermostat and other sensors. If the control board malfunctions, the furnace might fail to start or run inefficiently.

9. Air Filter

The air filter is a simple yet essential part of your furnace system. It’s responsible for trapping dust, dirt, and other debris before the air is circulated through your home. A clean filter ensures proper airflow and prevents dirt from entering the furnace components, which can cause them to wear out prematurely. Regularly changing the furnace filter is crucial for maintaining furnace efficiency and indoor air quality.

10. Pilot Light or Igniter

Older furnaces often use a pilot light to ignite the gas in the burner, while modern systems typically use an electronic igniter. The igniter generates heat to ignite the gas when the furnace is activated. If the pilot light or igniter fails, the furnace won’t be able to start, and you may need to replace the component.< ![graphic shows inside of furnace with furnace parts graphic shows inside of furnace with furnace parts]()

Why Choose Carrier Furnace Parts?

Choosing Carrier furnace parts ensures reliability, efficiency, and long-term performance for your heating system. Carrier designs its parts specifically for its furnaces, guaranteeing a precise fit and optimal functionality.1. High-Quality & Durable Components

Carrier furnace parts are built with premium materials to withstand harsh conditions and extend the lifespan of your system. Using genuine Carrier parts helps maintain the efficiency and safety of your furnace.

2. Enhanced Performance & Energy Efficiency

Authentic Carrier parts, such as heat exchangers, blower motors, and control boards, are designed to keep your system running smoothly. This helps maximize energy efficiency, reducing heating costs while maintaining consistent indoor comfort.

3. Expert Support

Carrier’s network of Factory Authorized Dealers ensures expert installation and service. For long-term reliability, efficiency, and peace of mind, choosing genuine Carrier furnace parts is the best way to protect your investment.

Talk To Your Carrier Dealer For More On Furnace Parts

A furnace consists of several components, each playing a vital role in the heating process. Understanding these parts can help you better maintain your system and troubleshoot issues when they arise. Regular furnace maintenance , such as replacing the air filter, checking for gas leaks, and inspecting the burner and heat exchanger, will help keep your furnace running efficiently and ensure your home remains comfortable throughout the winter months. Reach out to your local Carrier dealer for all of your furnace needs.

Frequently Asked Questions About Furnace Parts

Furnace parts include the burner (ignites fuel), heat exchanger (transfers heat), blower motor (circulates air), flame sensor (detects the flame), thermostat (regulates temperature), air filter (removes debris), and gas valve (controls fuel flow). Other components include the inducer fan, ignitor, and control board.

Signs that a furnace part needs replacement include strange noises, inconsistent heating, frequent cycling, blower not running, or unusual smells. Also, if the furnace won’t start or the pilot light goes out frequently, it may indicate a faulty part.

Furnace parts should be inspected and maintained annually. Regular maintenance, including cleaning filters, checking the blower, and inspecting the heat exchanger, ensures optimal performance, improves efficiency, and extends the lifespan of your furnace.

Furnace part replacement costs vary, typically ranging from $100 to $1,500 depending on the part. For example, a blower motor may cost $300 to $700, while a control board can cost $150 to $600. Labor fees add to the overall cost. Prices depend on the part and complexity.

The most common part to fail on a furnace is the ignitor. Over time, it can wear out or become dirty, preventing the furnace from lighting properly. Other common issues include the flame sensor, blower motor, and heat exchanger. Regular furnace maintenance helps prevent these failures.

The most expensive part to fix on a furnace is often the heat exchanger. If it cracks or fails, it can be costly to replace. Other expensive repairs can include the blower motor or the control board.

Furnace parts should be replaced as needed, with components like filters changed every 1-3 months, blower motors lasting 10-15 years, and heat exchangers typically replaced after 15-20 years, depending on wear and maintenance.

No, furnace parts should be installed by a licensed HVAC professional to ensure safety, proper function, and warranty compliance.

Warranty coverage varies by part and manufacturer. It can also depend on whether the HVAC system is registered.

Learn More About Furnaces

- How Much Does it Cost to Replace vs Repair a Furnace?

- Guide to Gas Furnaces

- Furnace Repair & Service

- How Do Gas Furnaces Work?

- Cost Of A Gas Furnace

- Gas Furnace Replacement

- Read about gas furnace repair

- Learn about furnace installation

- What is a high-efficiency gas furnace and how can it benefit me?

- 10 things to consider when buying a furnace

- Furnace troubleshooting tips

- Learn what to do if your furnace is leaking water

- How long does a furnace last?

- Comparing types of furnaces

- AFUE Rating (Annual Fuel Utilization Efficiency)

- Evaluating a Heat Pump vs Furnace

- Burning Smell in House? Causes and How to Fix It

- Learn the causes of a furnace not kicking on

- Learn about different HVAC system types