What is an AC Compressor?

The AC compressor is a vital component in your air conditioning system, responsible for circulating refrigerant to cool your home. Understanding how it works and how to maintain it can help ensure optimal performance and extend the lifespan of your AC unit. In this guide, we'll walk through what is an AC compressor, factors affecting A/C compressor cost and signs air conditioner compressor replacement is needed. Let's dive in!

What Is An AC Compressor?

An AC compressor is a crucial part of your HVAC system , playing a vital role in maintaining a comfortable indoor environment. It circulates and regulates refrigerant, which is essential for cooling your home.

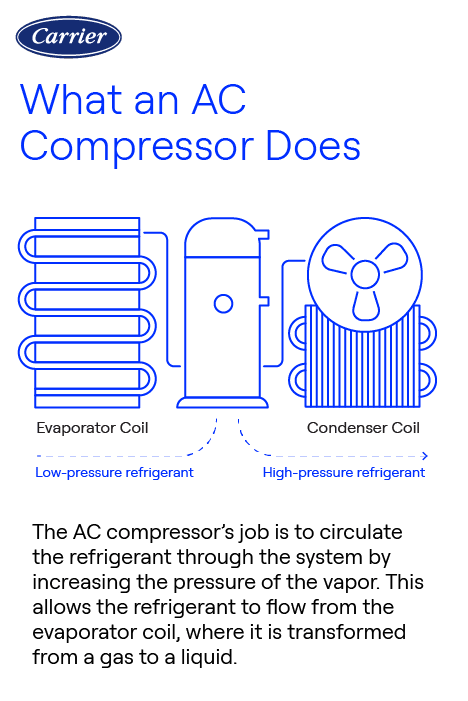

The primary function of the AC compressor is to compress refrigerant gas, raising its temperature and pressure. This high-pressure gas is then sent to the condenser coil, where it releases heat to the outside air and transforms back into a liquid. The cooled liquid refrigerant circulates through the evaporator coil , absorbing heat from the indoor air, thus making the air inside your home cooler. This cycle repeats to maintain a consistent and comfortable temperature. Learn more about how do air conditioners work .

A high-quality AC compressor is essential for the optimal performance of your air conditioning unit. A reliable and efficient compressor ensures that the cooling process is effective, which may result in lower energy consumption and reduced heating and cooling utility bills.

Understanding how an A/C compressor operates helps you appreciate its significance in maintaining a comfortable indoor climate. It is essentially the heart of your HVAC system, ensuring efficient and reliable cooling throughout your home.

Seven Factors Affecting A/C Compressor Replacement Cost

1. Compressor Type

2. AC Unit Size (Tonnage)

3. Brand and Model Compatibility

4. Installation Costs

5. Warranty Coverage

6. Efficiency and SEER2 Ratings

7. Location

Signs of a Failing Air Conditioner Compressor

- No Cool Air: If your AC is running but not cooling the air, a malfunctioning compressor could be the culprit. The compressor is responsible for circulating refrigerant through the system, and if it's not working properly, the refrigerant can’t absorb heat from the air, leaving the space warm.

- Strange Noises : A failing compressor may produce loud, unusual noises such as grinding, squealing, or banging sounds. These noises may indicate mechanical failure or internal damage.

- Increased Cooling Bills: If your compressor is struggling to operate, it may cause your AC to work harder, leading to higher energy consumption and noticeably higher cooling bills.

- Tripped Circuit Breaker: A compressor that's overloaded or faulty may cause the circuit breaker to trip repeatedly. This is often a safety feature to prevent further damage.

- Overheating: If the compressor is overheating, it may cause the AC unit to shut off prematurely, leaving your home uncomfortable.

A/C Compressor Repair vs. Replacement

Choosing the Right AC Compressor for Your Home

Benefits of Choosing Carrier AC Compressors

Energy Efficiency and Reliability

Cutting-Edge Technology and Features

Frequently Asked Questions About Compressors For AC Units

Several reasons could cause an air conditioning compressor not to turn on:

- Thermostat Issues: Check if the thermostat is set correctly and functioning. A faulty thermostat can prevent the compressor from receiving the signal to start.

- Electrical Problems: Issues such as tripped breakers, blown fuses, or faulty wiring can prevent power from reaching the compressor.

- Capacitor or Relay Problems: An AC capacitor or relay issue can prevent the compressor from starting properly.

- Low Refrigerant Levels: Insufficient refrigerant levels due to leaks can cause the compressor to shut down as a safety measure.

- Faulty Compressor: If the compressor motor itself is faulty or has failed, it may not start.

- Safety Switches: High or low-pressure switches or other safety devices may have activated due to system issues.

To diagnose and resolve the problem, it's advisable to contact a qualified HVAC professional who can perform a thorough inspection and repair any issues with your AC system.

The cost to replace an HVAC compressor depends on several factors:

- Type of Compressor: Different types of compressors (scroll, reciprocating, rotary) have varying costs.

- Brand and Model: The cost of the compressor can vary based on the brand and model of your AC unit.

- Labor Costs: Labor rates vary by location and the complexity of the installation.

- Warranty: If the compressor is still under warranty, you may only need to pay for labor costs.

For an accurate estimate, it's best to get quotes from your local Carrier dealer.

Deciding whether to replace a compressor on an AC unit depends on several factors:

- Age of the Unit: If your AC unit is over 10-15 years old, it might be more cost-effective to replace the entire unit, as other components may also start failing.

- Cost of Replacement: Compare this to the cost of a new AC unit.

- Warranty: If the compressor is under warranty, replacing it might be a good option since you may only pay for labor.

- Efficiency and Performance: Newer units are generally more energy-efficient. Upgrading could save on energy bills and offer better performance.

- Overall Condition: If the rest of the AC unit is in good condition and well-maintained, replacing the compressor might be worthwhile.

Consulting with an HVAC professional can help determine the best course of action based on your specific situation.

Symptoms of a bad compressor in an air conditioning system include:

- Warm Air: The AC blows warm or hot air instead of cool air.

- Noisy Operation: Unusual noises such as grinding, squealing, or rattling coming from the compressor.

- High Energy Bills: Increased energy consumption due to reduced efficiency.

- Frequent Cycling: The compressor frequently turns on and off.

- Tripped Breakers: The circuit breaker for the AC unit trips frequently.

- Visible Leaks: Signs of refrigerant leaks around the compressor.

- Ice Buildup: Ice forms on the refrigerant lines or coils.

If you notice any of these symptoms, it's advisable to have an HVAC technician inspect your system to diagnose the issue accurately and recommend the appropriate repairs or replacements.

An air conditioner compressor typically lasts between 10 to 15 years on average. However, several factors can affect its lifespan:

- Quality of Installation: Proper installation by a qualified HVAC technician can ensure longevity. Learn more about HVAC installation.

- Maintenance: Regular AC maintenance, such as cleaning coils and changing filters, can extend its life.

- Usage: Heavy use during hot seasons may shorten its lifespan.

- Environmental Factors: Exposure to extreme temperatures and weather conditions can affect durability.

Routine inspections by HVAC professionals can help identify issues early and prolong the HVAC compressor lifespan through timely repairs and maintenance.

Due to the complexity and potential hazards involved, it's strongly recommended to hire a qualified HVAC technician for compressor replacement. They have the technical knowledge and equipment needed to safely and effectively perform the job, ensuring your AC system operates efficiently and reliably.

Talk To Your Carrier Dealer About AC Compressors and AC Compressor Cost

At Carrier, we pride ourselves on our innovative technology. Our air conditioners include AC compressors with the latest advancements in cooling technology, so you can experience enhanced comfort and precise temperature control, even in the hottest summer months. Talk to your local Carrier dealer to learn more about A/C compressors and A/C compressor cost.

Learn More About HVAC Compressors

- Air Conditioner Maintenance Tips

- Help with Air Conditioner Service

- Troubleshoot an Air Conditioner tips

- Factors and variables - "How Long Do Air Conditioners Last?"

- Why you should get an AC Tune Up

- What is a split air conditioning system?